PROJECT : BACA ROBOT TRIAL – HARD ROCK STONE WORKS

PLACE : 44038 Phoenix Dr. Sterling Heights, MI 48314 U.S.A

DATE : 26th January 2021

COMPANY : Hard Rock Stone Works

CONTACT DETAILS : Bob Finn

EMAIL : bobf@hardrockstoneworks.com

WEBSITE : www.hardrockstoneworks.com

CLIENT :

Hard Rock Stone Works.

Who typically deal with Granite, Marble, Quartzite, Soapstone, and Engineered Quartz.

In 2017 alone, Hard Rock fabricated more than 60,000 square feet of stone for commercial projects.

PROJECT REQUIREMENTS :

1) Increase cutting speed on Baca Systems Robo SawJet – Cutting Dekton™ and Quartz

2) Cleaner cuts and fewer blowouts.

3) Directly dose the Robo SawJet with S-Complex™

4) Test compatibility with the recycled water system.

5) Optimize blade for high-speed cutting

CHEMFORCE SOLUTION :

The Robo SawJet water feed was directly dosed with 1% S-Complex™, with a Dema inline injector dosing pump.

RESULTS :

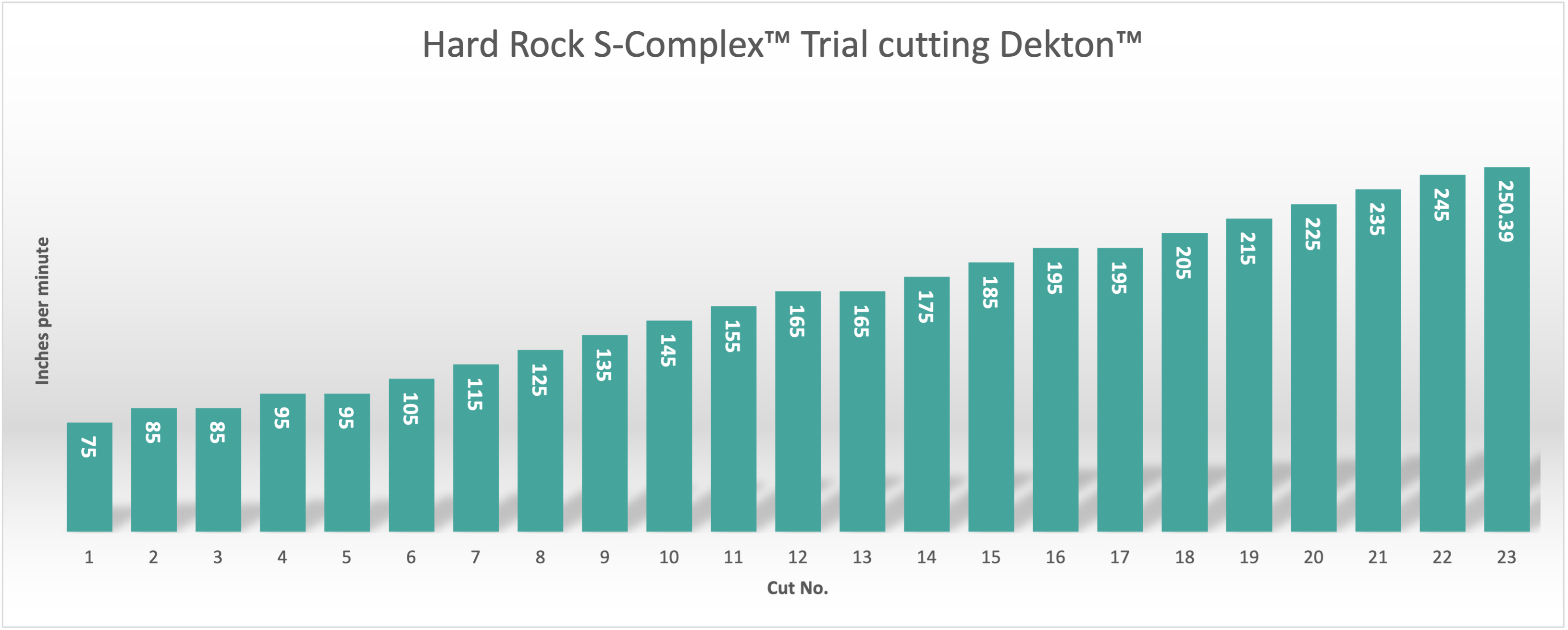

1) Cutting Dekton™ with Fresh water= 75 inches/Min (Typical cutting speed)

Cutting Dekton™ with S-Complex™= 250.39 inches/Min

Increase in production cutting Dekton™ by a factor of 3.3

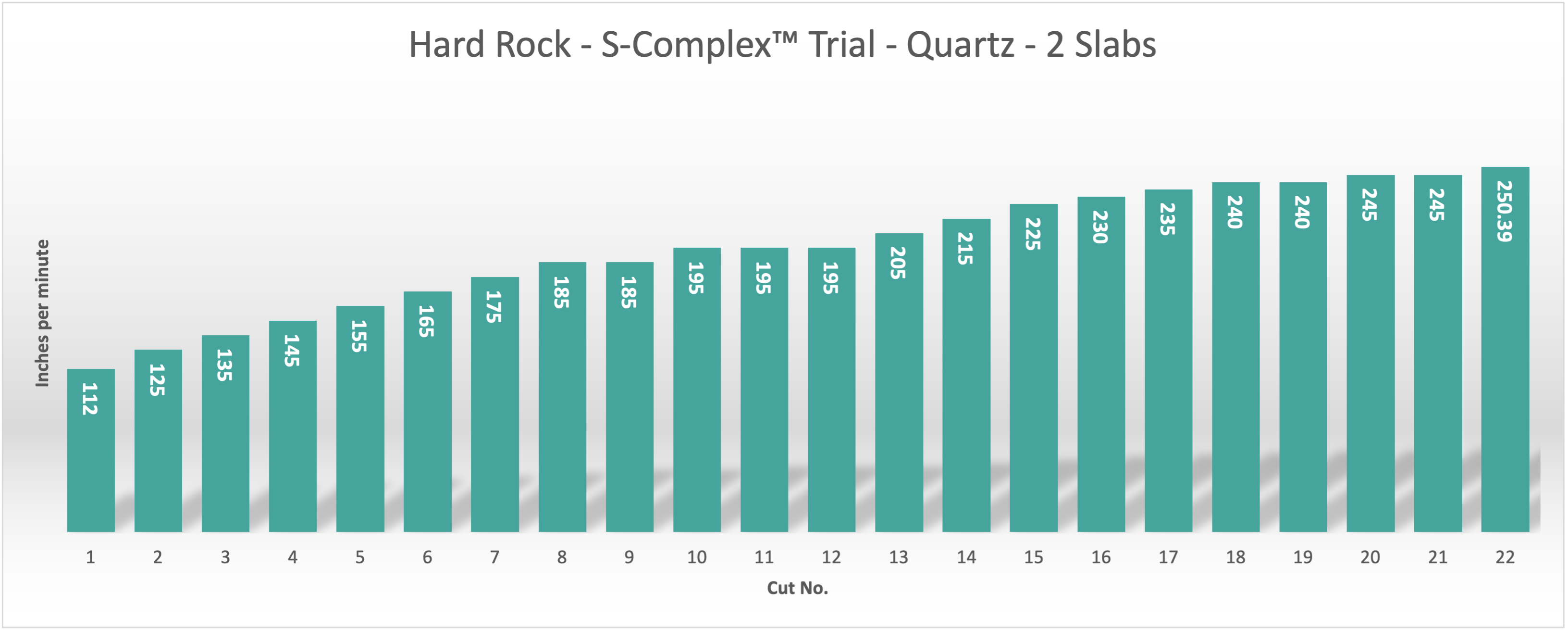

Cutting Quartz with Fresh water= 112 inches/Min

Cutting Quartz with S-Complex™= 250.39 inches/Min

Increase in production cutting Quartz by a factor of 2.2

2) Cleaner cuts on Dekton™ and Quartz.

3) S-Complex™ did not affect the recycling/filtration system.

NOTE: We were informed that they typically run the saw at 75inches/min and the fastest it had ever run was 145inches/min. After working with the team, we were able to comfortably cut the Quartz at the saw’s programmed maximum cutting speed, with no chips or blow-outs.

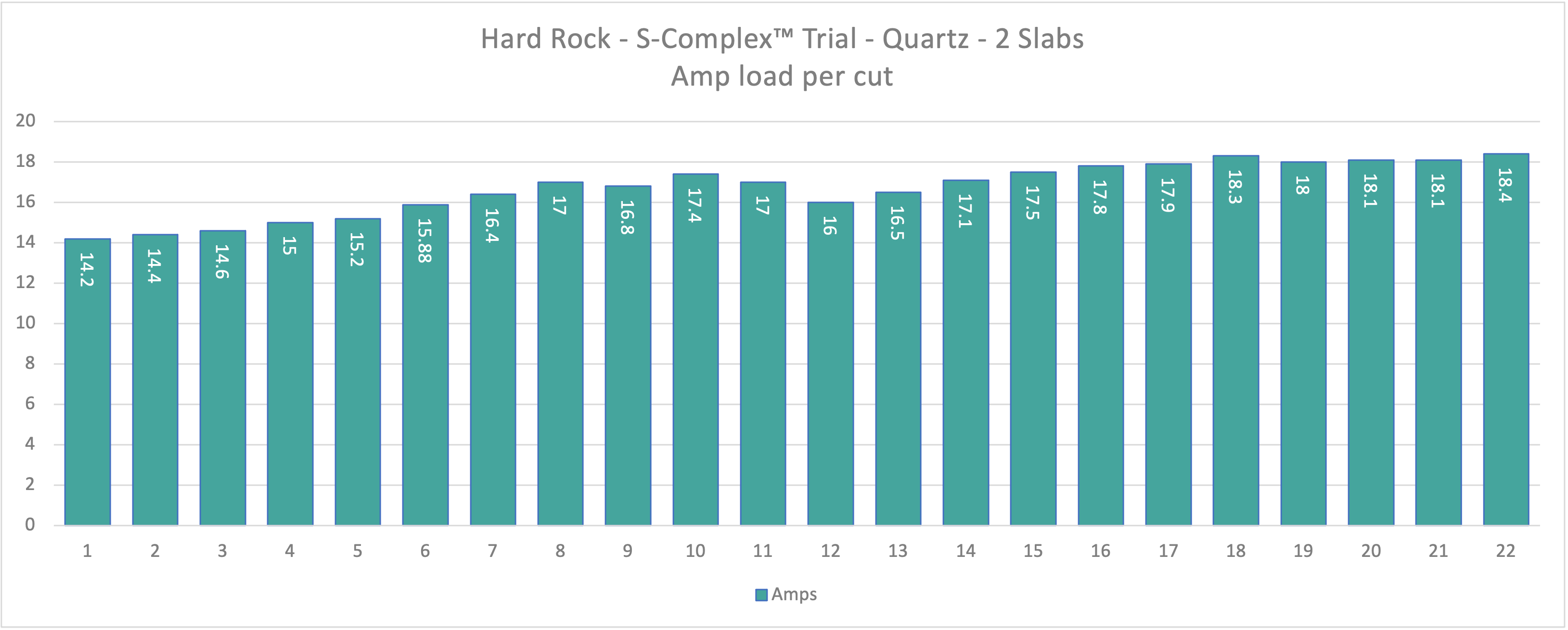

Note: Cuts 1 to 11 are on the first slab and 12 to 22 are on the second slab.

Note: The Amps are higher than seen on the Dekton™, although we are still able to achieve the maximum cutting speed of the saw with no chipping or excessive load on the robot.

Note: There is very little increase in the load on the system as the cutting speed significantly increases to the highest setting on the machine.

Note: There is very little increase in the load on the system as the cutting speed significantly increases to the highest setting on the machine.